Screen printing is a popular printing method that creates high-quality prints on various materials. However, after prolonged use, the screen printing screen may become dirty, reducing the quality of the prints. In this article, we will discuss the best tips and tricks on how to clean your screen printing screen effectively.

Cleaning your screen printing screen is an essential part of maintaining the quality of your prints. Whether you are a professional screen printer or a beginner, understanding how to clean your screen properly is crucial to achieving the best results. So, let’s dive in and discover the best ways to clean your screen printing screen!

- Remove any excess ink from the screen with a spatula or scraper.

- Wet the screen with water.

- Apply a screen cleaning solution to both sides of the screen.

- Scrub the screen with a soft brush or sponge, paying particular attention to the mesh.

- Rinse the screen thoroughly with water.

- Dry the screen with a lint-free cloth or allow it to air dry.

How to Clean Screen Printing Screen?

Screen printing is a popular printing method that involves pressing ink onto a surface through a mesh screen. To ensure clear and high-quality prints, it is essential to keep the screen clean. Here’s how you can clean your screen printing screen in 10 easy steps.

Step 1: Remove Ink

The first step in cleaning a screen printing screen is to remove any ink residue. You can do this by using a scraper or spatula to scrape off any excess ink. Once you have removed as much ink as possible, wipe the screen with a clean cloth to remove any remaining ink.

Step 2: Apply Emulsion Remover

Next, apply an emulsion remover to the screen. Emulsion remover is a chemical solution that dissolves the emulsion on the screen. Apply the emulsion remover to both sides of the screen and let it sit for a few minutes.

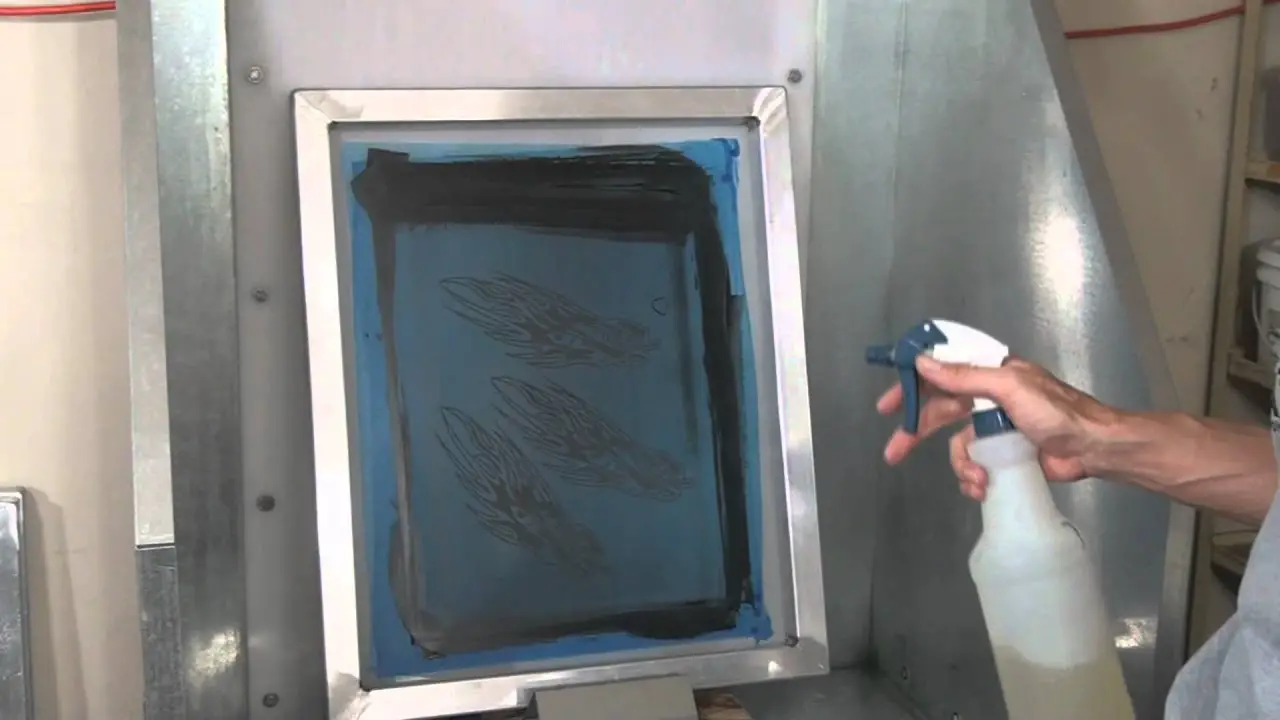

Step 3: Scrub the Screen

After the emulsion remover has had time to work, use a scrub brush to scrub the screen. Be sure to scrub both sides of the screen thoroughly to remove all traces of the emulsion.

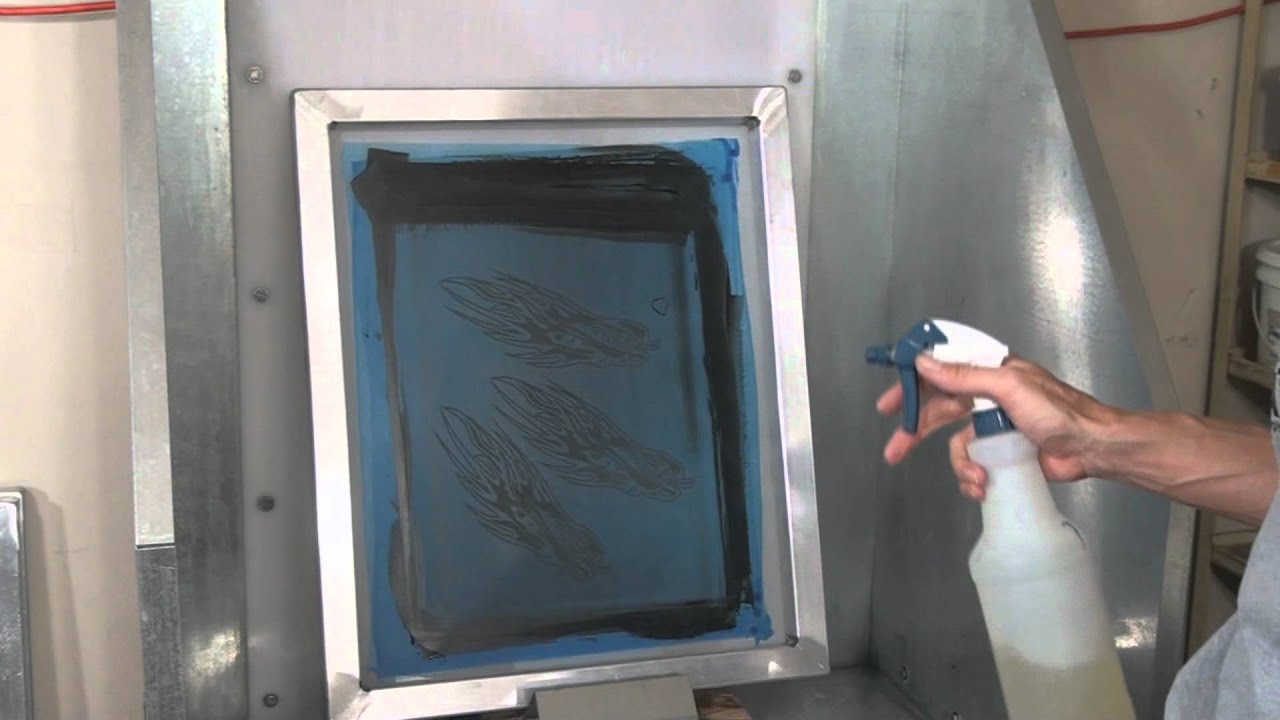

Step 4: Rinse the Screen

Once you have scrubbed the screen, rinse it off with a high-pressure hose or pressure washer. Rinse both sides of the screen thoroughly to remove any remaining emulsion remover and ink residue.

Step 5: Apply Degreaser

After rinsing the screen, apply a degreaser to the screen. Degreaser is a chemical solution that removes any oil or grease from the screen. Apply the degreaser to both sides of the screen and let it sit for a few minutes.

Step 6: Scrub the Screen Again

After the degreaser has had time to work, use a scrub brush to scrub the screen again. Be sure to scrub both sides of the screen thoroughly to remove any oil or grease.

Step 7: Rinse the Screen Again

Once you have scrubbed the screen, rinse it off again with a high-pressure hose or pressure washer. Rinse both sides of the screen thoroughly to remove any remaining degreaser.

Step 8: Dry the Screen

After rinsing the screen, use a clean, dry cloth to dry the screen. Be sure to dry both sides of the screen thoroughly.

Step 9: Inspect the Screen

Once the screen is dry, inspect it for any remaining ink residue, emulsion, or grease. If you notice any remaining residue, repeat the cleaning process until the screen is completely clean.

Step 10: Store the Screen

Finally, store the screen in a cool, dry place to prevent any damage or contamination. Make sure the screen is stored in a way that prevents it from being bent or damaged.

Cleaning your screen printing screen regularly is essential for producing high-quality prints. By following these 10 easy steps, you can keep your screen clean and in excellent condition for all your printing needs.

– Regular cleaning of your screen printing screen will ensure high-quality prints and extend the life of your screen.

– By keeping your screen clean, you can also reduce the risk of contamination and produce more consistent prints.

– Proper screen cleaning can also prevent damage to your screen, saving you money in the long run.

– Neglecting to clean your screen can result in poor print quality, contamination, and damage to your screen.

– While cleaning your screen may take time and effort, the benefits far outweigh the costs of neglecting to do so.

– Investing in proper cleaning supplies and regularly cleaning your screen can save you time and money in the long run.

Frequently Asked Questions

In this section, we have compiled some of the most commonly asked questions about how to clean screen printing screens. We hope these answers will help you keep your screens clean and extend their lifespan.

What is the best way to clean a screen printing screen?

The best way to clean a screen printing screen is to use a screen cleaner or degreaser. These products are specifically designed to dissolve ink and remove any residue left on the screen. To use them, apply the cleaner or degreaser to the screen and scrub it with a soft bristle brush. Rinse the screen thoroughly with water and let it dry before using it again.

It is important to avoid using harsh chemicals or abrasive materials, as these can damage the screen or cause it to lose its tension. Additionally, be sure to clean the screen as soon as possible after use, as dried ink can be much harder to remove.

Can I reuse the same screen cleaning solution?

You can reuse the same screen cleaning solution, but it is important to monitor its effectiveness. Over time, the solution can become contaminated with ink and other debris, which can reduce its cleaning power. To avoid this, it is recommended to change the solution every few screen cleanings, or whenever it appears to be losing its effectiveness.

Also, be sure to store the cleaning solution in a cool, dry place away from direct sunlight, as exposure to heat and light can also reduce its effectiveness.

How often should I clean my screen printing screens?

You should clean your screen printing screens as soon as possible after use. Leaving ink on the screen for too long can cause it to dry and become much harder to remove. Additionally, regular cleaning can help prevent buildup of ink and debris on the screen, which can affect the quality of your prints.

How often you need to clean your screens will depend on how frequently you use them. If you are printing every day, you may need to clean the screens after each use. If you are printing less frequently, you may be able to clean the screens every few uses.

Can I use water to clean my screen printing screen?

Water can be used to clean a screen printing screen, but it may not be effective at removing all types of ink and residue. Additionally, using water alone can cause the screen to become waterlogged and lose its tension over time.

If you do use water to clean your screens, be sure to use a minimal amount and to dry the screen thoroughly afterward. It may also be helpful to use a screen cleaning solution or degreaser in conjunction with water for best results.

What should I do if my screen printing screen is damaged?

If your screen printing screen is damaged, you may be able to repair it using a screen patch or emulsion remover. However, if the damage is severe, it may be necessary to replace the screen entirely. To prevent damage to your screens, be sure to handle them with care and avoid using harsh chemicals or abrasive materials when cleaning them.

Regular maintenance and cleaning can also help extend the lifespan of your screens and reduce the risk of damage or wear and tear over time.

Screen Printing Hacks | How to Clean Ink from Screens [ 2 INK CHANGE OUT TIPS ] t-shirt business.

In conclusion, cleaning your screen printing screen can seem like a daunting task, but with the right tools and techniques, it can be a breeze. By using the proper cleaning solution and a soft-bristled brush or cloth, you can effectively remove ink and debris from your screen without damaging it.

Remember to always clean your screen after each use to prolong its lifespan and ensure the quality of your prints. Regular maintenance and cleaning will save you time and money in the long run.

With these simple tips, you can keep your screen printing screen in top condition and produce high-quality prints every time. Happy printing!